Direct Drive Versus Belt Driven Fans

In the later there is a belt sometimes more than one connecting the motor to move the fan.

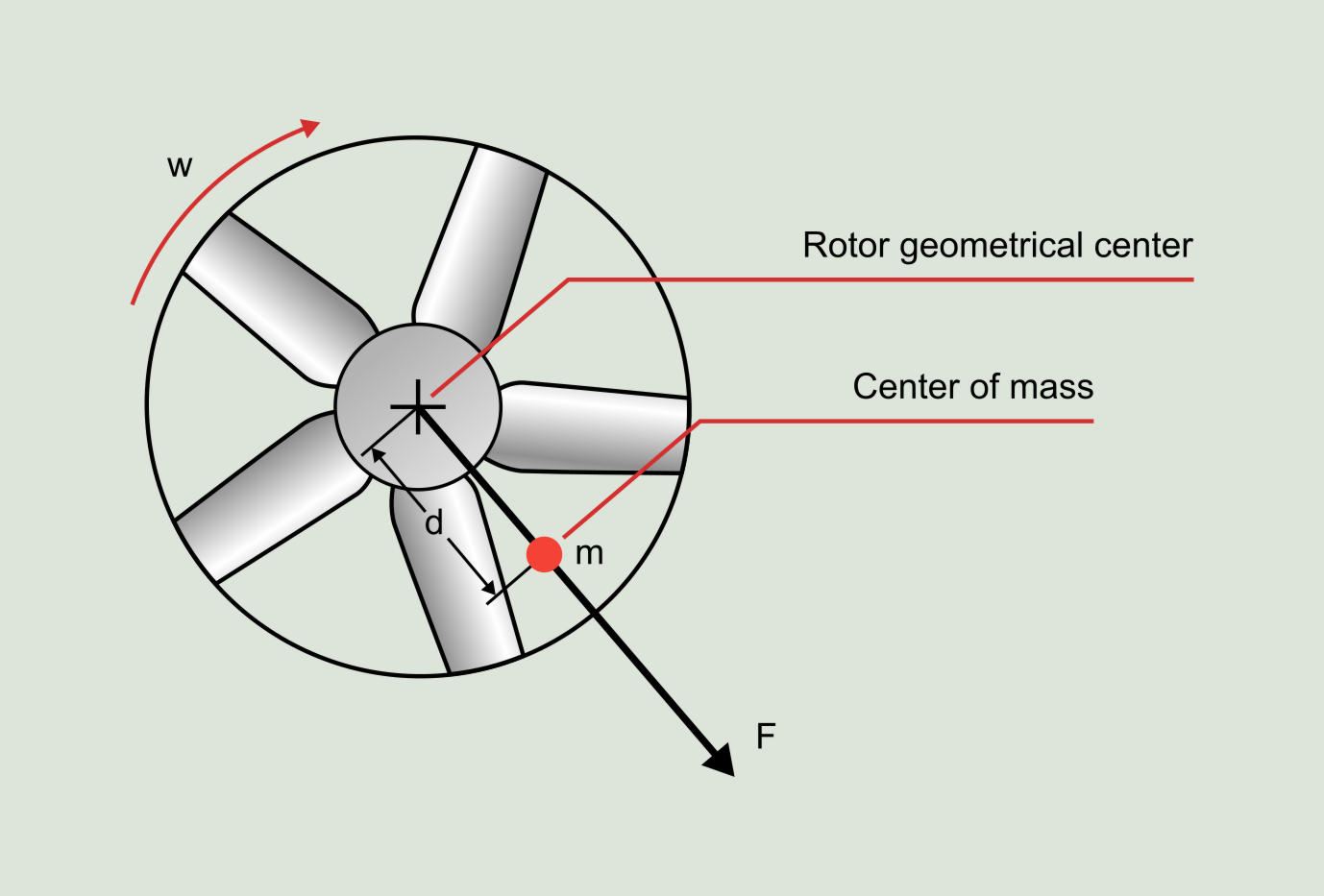

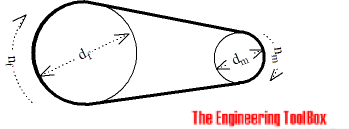

Direct drive versus belt driven fans. Direct drive fans should be designed for acceptable bearing life. Thus the fan blades will rotate at the same speed as the motor rotates. Greater efficiency is the biggest pro of direct drive fan configurations. The second pulley is connected to a shaft that drives the fan propeller.

The two bearings on direct drive fan motors which are 7 horsepower and larger are typically regreaseable. It s a motor connected to your fan in one of only two ways. Deciding between a direct drive fan and a belt drive fan is fairly straightforward once you know all of your other variables like fan size application space fan speed needs and likely wear and tear in your application. Direct drive or belt drive.

With the growing acceptance and affordability of vfd motor controllers direct drive fans are increasingly finding their way into mainstream industrial fan applications. This is because of the fact that the amount of friction is greatly reduced in case of this fan when the fan is operating. On a direct drive fan as implied by the name the fan propeller is connected directly to the shaft of the motor. More often than not the maintenance cost of this kind of fan is also comparatively lower.

Where on a belt drive fan the fan motor shaft has a pulley connected by a belt to a second pulley. While both belt and direct drive fans have been around for a long time the mainstay fan for most industrial fan applications under 250 hp has been the belt drive fan. Unlike the belt driven fans in case of a direct drive fan there is lesser energy loss. Unlike belt driven fans there s less energy loss because there s a reduced amount of friction as the fan operates.

Direct drive fans have no power transmission loss since the propeller is directly connected to the motor shaft. In the former the motor connects to the fan wheel with nothing in between.