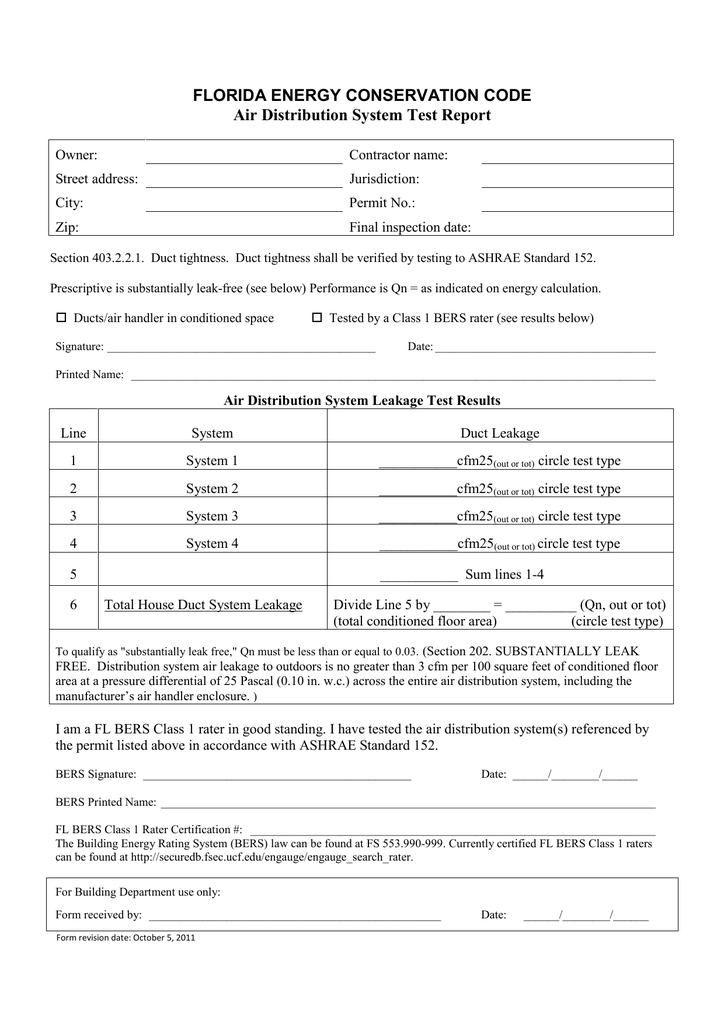

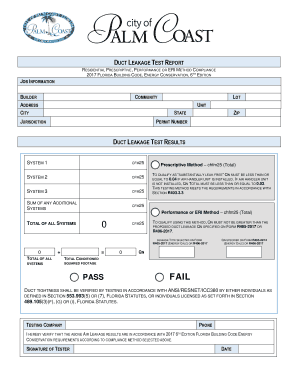

Duct Leakage Test Results

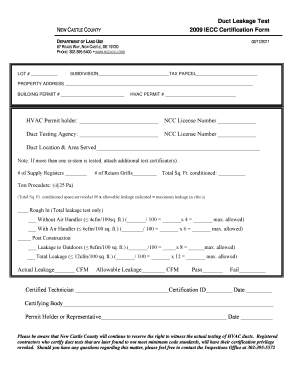

A duct leakage test duct testing can be performed at rough in before drywalling or post construction.

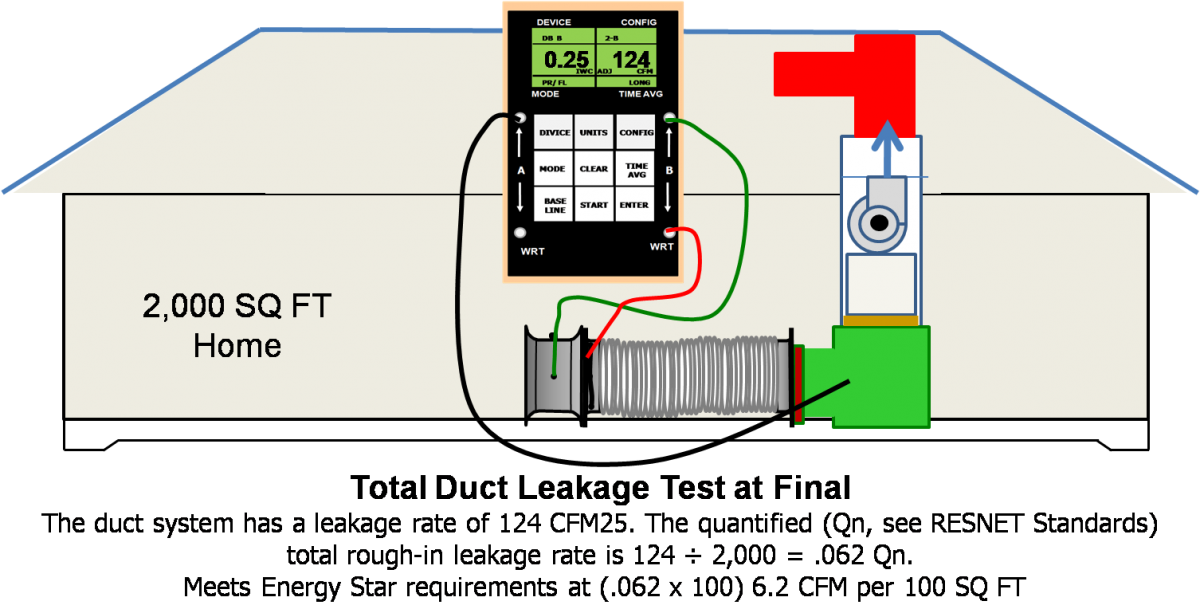

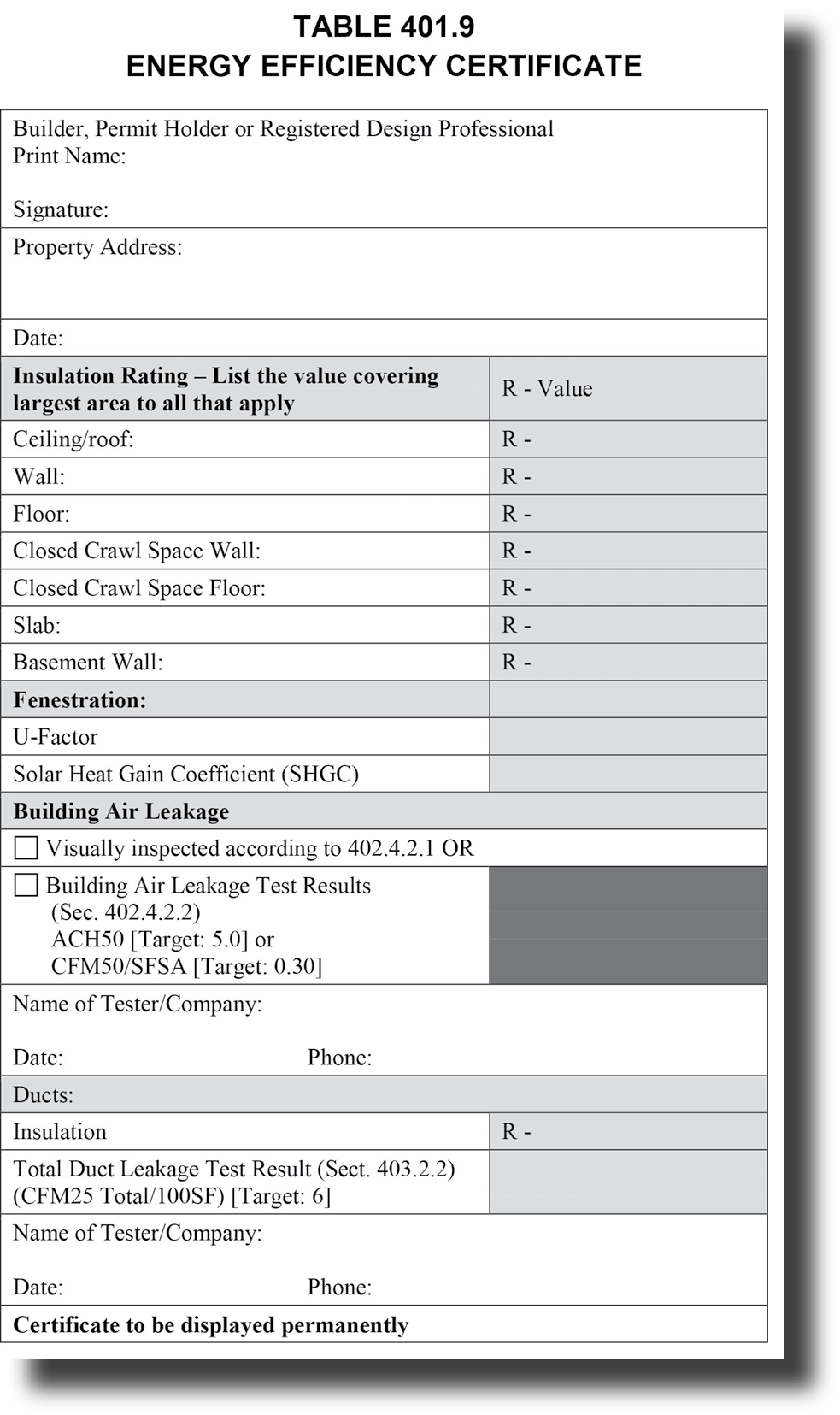

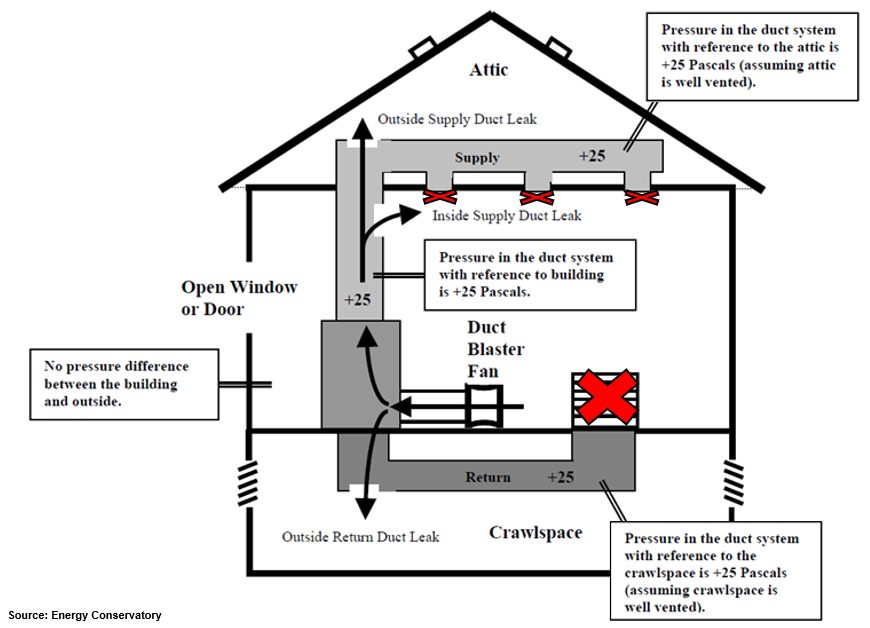

Duct leakage test results. A duct leakage tester is a diagnostic tool designed to measure the airtightness of forced air heating ventilating and air conditioning ductwork. Irc 2015 n1103 3 4 allows the following duct leakage. An appropriate leakage rate that results in minimal leakage at minimal expense. A 2 5 ton cooling system moves 1 000 cfm of air and puts out 30 000 btu h.

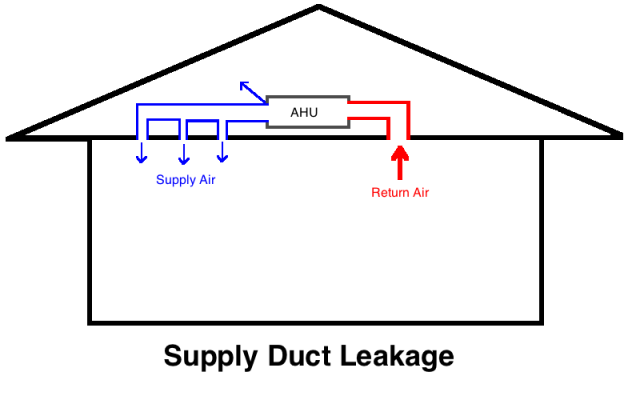

The system will need to achieve a leakage rate of less than 4 cfm cubic feet per minute per 100 square feet of the home. Duct leakage test results existing construction washington state energy code reference. In both cases the requirements are the same. If the air handler is not yet installed we will test the supply and return sides of the system independently and add the 2 leakage totals together to determine the total leakage.

Sampling townhouse communities and multifamily properties with 10 or more dwelling units must request dcra s approval to utilize sampling. Us duct leakage testing ri trequirements smacna duct class 1 2 inwg 3 inwg 4 6 10 inwg seal class cb a sli t transverse joints seams sealing applicable ransverse joints only asvese joints and seams jo s sea s and all wall penetrations leakage class c l cfm leakage per 100 ft2 1 in h 2 o rectangular. The airtightness of ductwork is useful knowledge when trying to improve energy conservatio. It is table 4 1 on page 4 3 in the 1985 smacna hvac air duct leakage test manual and table 1 1 on page 1 11 in the 2005.

However our local utah code has a carve out allowing 7 cfm per 100 sq ft. Rough in test less than 4 cfm per 100 sq ft which for my house is about 160 cfm if the air handler is included in the leakage test. Does table 1 look familiar. A duct leakage tester consists of a calibrated fan for measuring an air flow rate and a pressure sensing device to measure the pressure created by the fan flow.

Th e designer should carefully consider the following information in establishing allowable leakage specifi cations. The combination of pressure and fan flow measurements are used to determine the ductwork airtightness. Each cubic foot of air moved will carry with it 30 btu h. R101 4 3 1 mechanical systems when a space conditioning system is altered by the installation or replacement of space conditioning equipment including replacement of the air handler outdoor condensing unit of a split system air conditioner or heat pump cooling or heating coil or the furnace heat exchanger the duct system that is connected to the new or replacement space conditioning equipment.

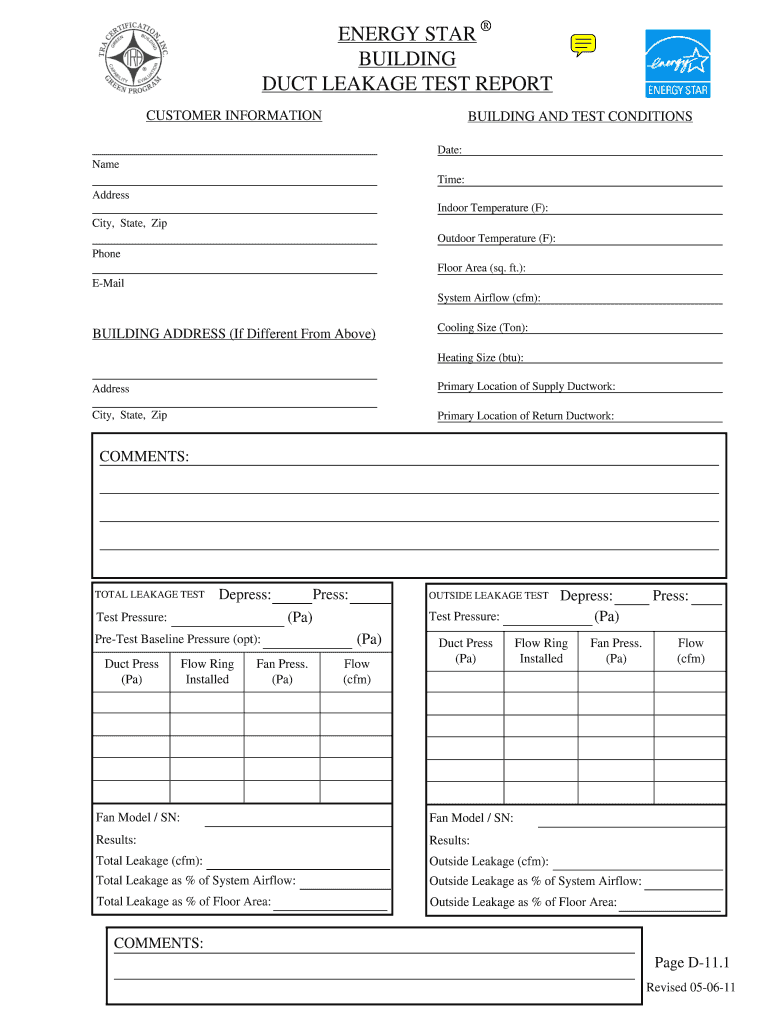

Duct leakage test results rough in test air handler installed total leakage 6 cfm per 100 ft2 of conditioned floor area tested at a pressure differential 25pa 0 1 in w g across roughed in system all register boots taped or otherwise sealed.